Traction Agv Rail Guided Vehicle for Agv Material Handling

Intelligent WarehouseAutomated warehouse system can complete the automatic access of unit goods under the control of the;

Basic Info.

| Model NO. | RGV-1000 |

| Mobility | Mobile |

| Height | 5-15m |

| Weight | Max. 900 Kg |

| Closed | Closed |

| Development | New Type |

| Serviceability | Common Use |

| Transfer Speed | 12m/Min |

| Transfer Type | Chain RF50-2X3 |

| Walking Time | (Go Time) 12s / (Return Time) 12s |

| Walking Speed | 23600 mm |

| Total Time | 12+12+17+17≒60s |

| Processing Power(Max.) | 3600/60=60pl/Hr |

| Transfer Time | (Pickup Time) 17s / (Unloading Time) 17s |

| Transfer Distance | 1400 mm |

| Rgv Height | 700 mm |

| Track Length | About 25m |

| Rgv Acceleration | 0.8 M/S2 |

| Rgv Speed | 125 M/Min(Actual); Max. 160 M/Min. |

| Track | Iron |

| Goods Weight | Max. 900 Kg |

| Type 1 | Linear Reciprocating |

| Transport Package | Film+Hardboard; as Your Requirements |

| Specification | Customized |

| Trademark | MIC |

| Origin | China |

| HS Code | 73089000 |

| Production Capacity | 200 PCS/Month |

Product Description

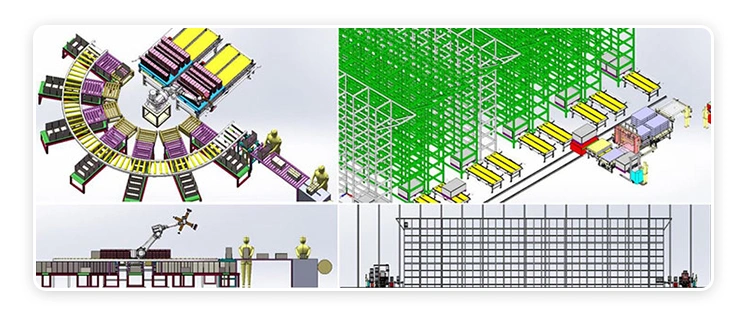

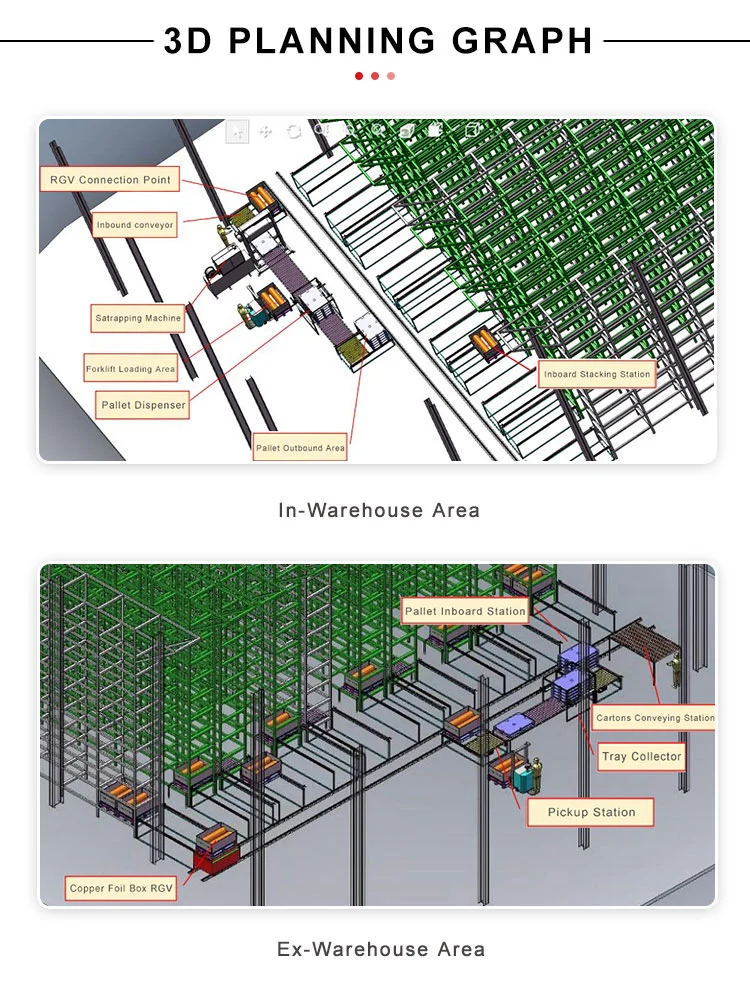

System ComponentsTransfer and storage of goods - high shelves and pallets, containersInbound and outbound operation equipment - stackers, shuttles, RGVs, AGVs, etc.Inbound and outbound distribution system - roller, chain conveyor, dispenser, lifter, etc.WCS control system - including computer-controlled inbound and outbound equipment, distribution systems, and all electronic control devices for various inspection and insurance agenciesWMS warehouse management system - warehouse account management, data analysis, reasonable management of the location, equipment operation and inventory status display, etc.

In the automated logistics conveying system, RGV is an important conveying equipment. Its structure is simple,maneuverable and flexible. According to the site working conditions, you can choose straight line operation, ring-type operationor Heavy-duty traverse operation. The automated shuttle can replace a large number of ordinary conveying equipment and its automatic control efficiency is high.

| RGV Model | RGV-1000 |

| Type | Linear Reciprocating |

| Track | Iron |

| Goods Weight | MAX. 900 KG |

| Track Length | About 25M |

| Height | 700 mm |

| RGV Speed | 125 m/min(Actual); MAX. 160 m/min. |

| RGV Acceleration | 0.8 M/S2 |

| Walking Speed | 23600 mm |

| Walking Time | (go time) 12s / (return time) 12s |

| Transfer Speed | 12m/min |

| Transfer Type | Chain RF50-2x3 |

| Transfer Distance | 1400 mm |

| Transfer Time | (pickup time) 17s / (unloading time) 17s |

| Total Time | 12+12+17+17≒60s |

| Processing Power(Max.) | 3600/60=60PL/HR |

| Power Supply | 3P Electric Rail |

| Communication Method | Wireless |

| Quantity | 2 |

What Are The Advantages of RGV Systems?

RGV Systems are easy to install, highly scalable and easy to maintain. In each system the vehicles can easily be removed and replaced for maintenance or upgrade without affecting the overall operation of the system.

The systems can be set up in linear or circular patterns depending upon the location and production requirements.

- Scalability

- Availability

- Transport Speed

- Efficient Automated Material Flow

- Simple Layout for Controlled Distribution

- Frequent Vehicle Position Updates

- Short Dead Reckoning Distances

- Independent Vehicle Operation Possible

- Heavy Lifting Capacity

A: Manual Installation SOP, video support, on-line support. Also engineers overseas.3.What's your payment way?T/T by our bank account directly, or by MIC trade assurance service, or cash,and others.4.How can we make sure about the product quality after we put the order?Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in the third party inspection organization.5.we are afraid you won't send us the products after we send you the money?Please note our above business license and certificate. And if you don't trust us, then we can use MIC trade assurance service or payment by LC,guarantee your money.6.Is it possible to negotiate to obtain the agency rights of your products?We currently have our own branches in eight countries or regions, but we are very happy to cooperate with each other through mutual benefit. We can provide agents with professional skills training and the right to sell consumable accessories, so that we can achieve better results and score btogether.

You may also like

Send inquiry

Send now